Delivering Excellence

through Innovation

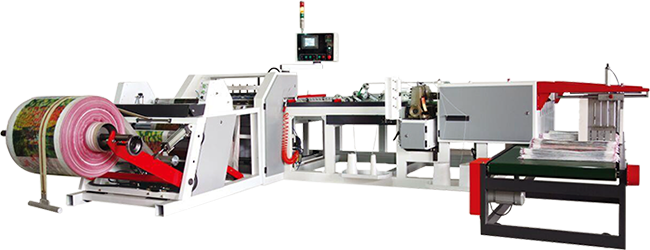

HDPE / PP

Automatic Woven Bags Conversion

Line - BCS

To straighten all types of M.S. / Aluminum Pipes(tubes)

which are used in tape / thread winding applications.

Description

N-TEX Automatic Woven Sacks Roll to Bag Conversion Line complete with all standard components and standard accessories.

Areas of Application

To Make / Cut and Stitch

- Laminated / Non Laminated HDPE / PP Woven Sacks Raffia Bags from Woven Sacks Roll

Production Capacity

Up to 28 to 50 Bags / Minute (Speed depend on Bag Cut Length / Size)

Special Feature

Magnetic Bag Griper at 90°